Ball bearing types are essential components in mechanical systems, responsible for minimizing friction and supporting radial and axial loads in heavy-duty machinery. Understanding the nuances of each type helps engineers and maintenance professionals select the most suitable bearing for specific applications, ensuring reliability and extended service life. In the commercial vehicle industry, the choice of bearing impacts operational efficiency, fuel economy, and maintenance intervals.

KG International offers a comprehensive portfolio of ball bearing types tailored to meet diverse industrial demands. Whether it is high-speed wheel hubs, precision gearboxes, misaligned shafts, or thrust-heavy steering systems, choosing the correct bearing design is critical. This blog explores the four most common ball bearing types—deep groove, angular contact, self-aligning, and thrust—highlighting their design features, load-carrying capabilities, and ideal use cases. By the end of this guide, you will have the insights needed to optimize bearing selection for your specific commercial vehicle application.

1. Deep Groove Ball Bearings

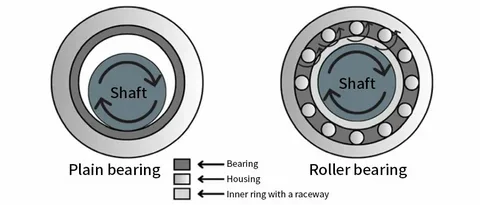

Deep groove ball bearings are the most widely used bearing type, prized for their simplicity and versatility. Their uninterrupted, deep raceway grooves allow smooth operation under both radial and light axial loads.

Key Features:

- High-speed capability with low friction

- Simple design, easy to mount and maintain

- Can accommodate moderate axial loads in both directions

- Available in a variety of sizes and materials

- Sealed and shielded options for contamination protection

Ideal Applications:

- Wheel hubs and axles

- Electric motors and generators

- Pumps and gearboxes

- Agricultural and construction machinery

- Conveyor and material handling systems

Performance Benefits:

- Reduced energy consumption due to minimal friction

- Enhanced durability under dynamic loads

- Consistent performance across wide temperature ranges

- Low noise and vibration levels

- Cost-effective solution for general-purpose needs

Maintenance Tips:

- Regular lubrication intervals to prevent wear

- Monitor for contamination—use seals or shields where necessary

- Inspect for raceway or ball defects during scheduled downtime

- Replace bearings as a matched pair in critical applications

- Use proper mounting tools to avoid damage

2. Angular Contact Ball Bearings

Angular contact bearings feature raceways displaced at an angle to the bearing axis, enabling them to support combined radial and axial loads.

Key Features:

- Contact angles typically range from 15° to 40°

- High axial load capacity in one direction

- Available as single-row, double-row, and four-point contact types

- Preload capability for rigidity and precision

- Can be paired back-to-back or face-to-face

Ideal Applications:

- Precision truck gearboxes and transmissions

- High-speed spindles in machining centers

- Steering and suspension assemblies

- Pump and compressor shafts

- Aerospace control systems

Performance Benefits:

- Superior stiffness under combined loads

- High rotational accuracy for precision applications

- Ability to handle rapid acceleration and deceleration

- Improved load distribution reduces bearing stress

- Enhanced service life under heavy-duty conditions

Installation Guidelines:

- Correct preload adjustment to balance rigidity and friction

- Pair bearings symmetrically to handle bidirectional axial loads

- Use precision mounting jigs for alignment

- Maintain a clean assembly environment to prevent contamination

- Verify bearing orientation per manufacturer specifications

Design Considerations:

- Select an appropriate contact angle based on axial load requirements

- Material choices (chrome steel, ceramic) for speed and temperature

- Cage design options (brass, polymer) for noise and lubrication

- Heat treatment and surface finish for extended fatigue life

- Consider misalignment tolerances in system design

3. Self-Aligning Ball Bearings

Self-aligning ball bearings incorporate two rows of balls with a common, spherical outer raceway, allowing automatic alignment under shaft deflection.

Key Features:

- Spherical outer ring raceway corrects misalignment up to 3°

- Two rows of balls share the load, distributing stress evenly

- Low starting torque due to smooth ball movement

- Tolerance for shaft bending and housing deflection

- Available in open, sealed, and shielded versions

Ideal Applications:

- Truck drive shafts and propeller shafts

- Belt and chain conveyor pulleys

- Paper and textile machinery

- Agricultural equipment and harvesters

- HVAC fan and blower assemblies

Performance Benefits:

- Reduction of edge stresses in misaligned systems

- Improved service life in flexible or deflecting shafts

- Smooth operation at moderate speeds

- Simplified mounting process—less precise housing bores needed

- Lower maintenance requirements in misalignment-prone assemblies

Installation and Maintenance:

- Ensure the housing bore allows self-aligning movement

- Use light lubrication—excess grease can impede alignment

- Monitor temperature; overheating may indicate misalignment beyond tolerance

- Inspect housing fit and shaft straightness periodically

- Replace bearings when the spherical raceway shows wear

Design Tips:

- Calculate expected misalignment and select bearing accordingly

- Review load distribution—ensure combined radial/axial loads are within limits

- Pair with compliant couplings to maximize system flexibility

- Incorporate seals if contamination is a concern

- Choose bearing width for enhanced rigidity under radial loads

4. Thrust Ball Bearings

Thrust ball bearings are designed exclusively for axial loads, featuring flat washers with grooved raceways and balls between them.

Key Features:

- Supports axial loads in one or two directions

- Simple construction with separable washers and ball assembly

- Low friction for axial movement

- Available in single-direction and double-direction designs

- Various cage materials for different speed and temperature needs

Ideal Applications:

- Truck steering columns and linkages

- Low-speed rotary tables and turntables

- Marine rudder and stabilizer systems

- Presses and lifting mechanisms

- Valve stems and swivels

Performance Benefits:

- Precise axial positioning under high thrust

- Minimal friction for smooth axial motion

- Easy inspection and replacement due to a separable design

- Compact form factor for space-limited applications

- High rigidity under pure axial loading

Usage Guidelines:

- Align thrust faces parallel to mating surfaces

- Apply appropriate preload to eliminate play

- Lubricate thrust washers evenly to prevent wear

- Avoid radial load exposure—use back-to-back arrangements for combined loads

- Inspect bearing faces for pitting and scoring

Design Recommendations:

- Select ball diameter and washer curvature for load capacity

- Choose cage material based on speed and lubrication environment

- Incorporate axial clearance per application requirements

- Use hardened washers for high-load endurance

- Consider thermal expansion in high-temperature settings

Conclusion

The proper selection of ball bearing types is key to enhancing the functionality and durability of commercial vehicle components. Deep groove bearings offer versatile radial and light axial load support. Angular contact bearings deliver the stiffness and precision needed for high-speed gearboxes and spindles. Self-aligning bearings simplify maintenance in misaligned shafts, while thrust bearings guarantee accurate axial positioning under heavy thrust conditions. By understanding the unique design features and application best practices for each bearing type, engineers can enhance system efficiency, reduce downtime, and improve overall cost-effectiveness. KG International provides a full spectrum of bearing solutions tailored to withstand the rigorous demands of the mechanical and commercial vehicle industries. Visit KG International to explore their complete range, leverage expert guidance, and select the perfect bearing solution for your next project.